Capabilities

Atech Manufacturing is Silicon Valley’s single source for traditional and custom high-precision CNC machining and small to mid-sized turnkey assembly solutions.

The following is a comprehensive range of professional services and capabilities available across all the industries we serve. Additional services can be made available on request.

Contact Atech Manufacturing to learn more.

View Capabilities Chart

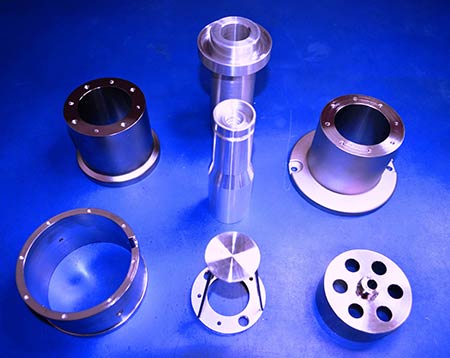

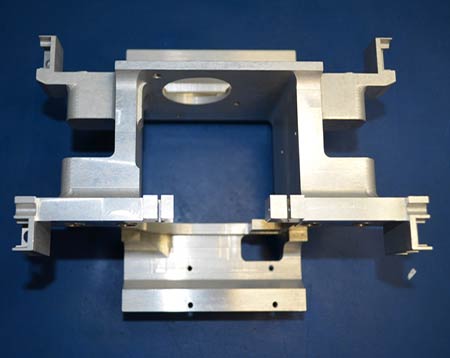

Machining and Fabrication

- High-precision CNC machining

- Prototype-to-production quantities available

- New product introduction (NPI)

- Quick turnaround, with high precision and quality

- Fixturing, for complex parts

- Sheet metal parts, small and large sizes

- Traditional, exotic, and precious metals

- Plastics, castings, and welded parts

- Industry standard software

- Industry standard file formats

Project Management

- Cost-effective single source project management, from concept to completion

- Collaborate with customer engineers throughout a project

- Fully integrated manufacturing and turnkey assembly solutions

- Manufacture upgrades to improve product designs throughout a project

- More than 150 man-years of machining and assembly experience

- Allied Partner Services collaboration to ensure total solution commitment

- Allied plating, painting, and chemical cleaning for clean room environment, crating, silk-screening, laser engraving, and labeling

- Industry focused: semiconductor, biomedical, automotive, solar, automation, aerospace/defense

- Worldwide customer service

- On spec, on time delivery

- Fully warranted workmanship

- Our project management skills and capabilities provide comprehensive oversight for all phases of product design and development, up to and including industrial scale logistics.

Assembly

- Turnkey systems: Electromechanical assemblies and contract manufacturing

- Kanban and JIT system support, including long product lead times

- New Product Introductions (NPI)

Quality Management

- ISO 13485, ISO 9001, RoHS

- Total Quality Management (TQM)

- In-process and final inspections, including first articles

- Calibrated QC tools for all type of manufacture

- Manufacture upgrades to continually improve overall process

- Customer satisfaction guaranteed

Core Services

Atech Manufacturing’s core services provide broad support for customer engineering departments in the design and development of initial prototypes to full scale production quantity runs. This collaborative effort helps streamline and simplify manufacturing processes while providing measurable cost savings.

Equipment

Atech Manufacturing uses state-of-the-art machining and quality control tools to consistently deliver manufactured products of the highest possible quality. The following is a partial list of available equipment. Contact us directly to inquire about our extended tool roster.

Innovate with Atech

Industries continually evolve products and systems to remain competitive. Atech Manufacturing combines years of proven expertise and comprehensive project management capabilities to bring customer innovations of every size, shape, and material to life. Together with our comprehensive suite of core services and state-of-the-art equipment, we stand ready to create the parts, components, and complete turnkey assemblies most in demand.

Contact Atech Manufacturing today to request a quote on an upcoming project. And be sure to bookmark this site for fast and easy future reference.

Atech Manufacturing, 1530 Oakland Road, Suite 120, San Jose, California-95112.