Turn-Key Assembly

Atech Manufacturing turnkey assembly projects integrate precision machining, in-house assembly, inspection and certification, and as-required specialty services, including operational method sheets (OMS). Typically, assemblies combine machined, sheet metal, and commercially available original equipment manufacturer (OEM) parts. Final assemblies can vary greatly in both size and complexity.

Single-Source Project Management

Our single-source project management approach excels at achieving concept-to-completion efficiencies across the entire turnkey design, development, and manufacturing process. Established Kanban workflow and Just-In-Time (JIT) inventory control systems fully support and accommodate long production lead times, locally and globally.

Kanban Project Management

Atech Manufacturing supports Kanban Project Management, a workflow optimization tool in which product production and continual product delivery is in sync with product demand forecasts.

We follow six generally accepted Kanban rules to ensure success:

- No products are made or moved without a Kanban workflow in place.

- A Kanban must be in place for every step of the production workflow.

- Manufacture products in only the specified amount and sequence.

- Customer product withdrawals are done the in specified amount only.

- Defective products and incorrect production volumes never move downstream.

- Minimize the number of Kanbans to effectively modify processes and reduce required inventory levels.

JIT Inventory Management

As with Kanban, our Just-In-Time (JIT) inventory management strategy ensures material procurement and product production are in sync with product demand. JIT strategies help streamline workflow processes, minimize raw material costs, and reduce material waste, thereby effectively reducing inventory costs.

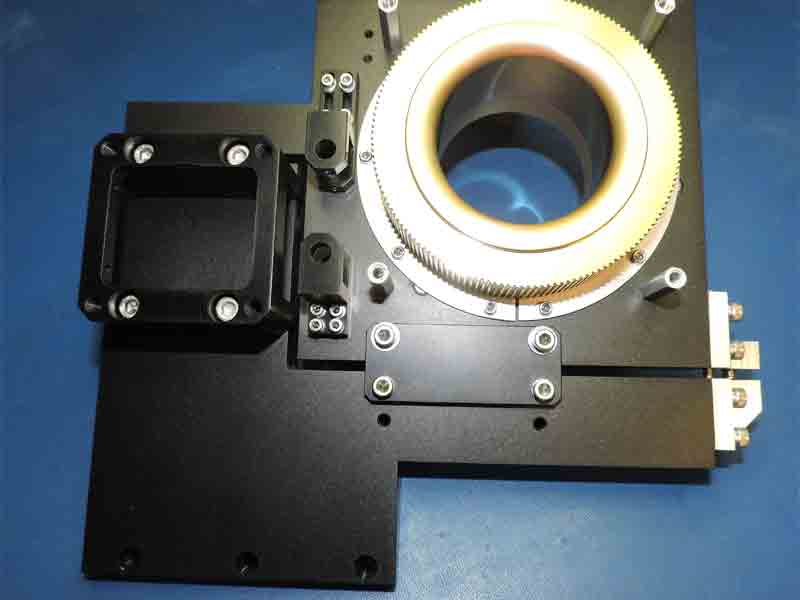

Small Turn-key Assemblies

Large Turn-Key Assemblies

Atech Turn-Key Assembly Process

We first review the project Request for Quotation (RFQ)—product diagrams and drawings, complete design specs, a bill of materials (BOM), timelines, and budget, and any special requirements—to fully understand project deliverables. If we have questions, we initiate a Q&A to clarify any outstanding issues.

Atech Manufacturing provides an all-inclusive itemized price quote that covers every in-house, OEM, and OTS part or component within the scope of the project, from concept to full assembly, including contingencies.

With the usual and customary work agreement signed and approved by both parties, the customer generates a purchase order (PO), which we then review and, upon confirmation, initiate project work. OEM and/or OTS parts procurement, in-house production timetables, quality control points, customer approvals, and final testing set the pace for timely completion and shipping.

Streamlined Production

Atech Manufacturing streamlines production for all manner of high- and low-volume parts and electromechanical components, as well complete system assemblies in our fully certified facility.

Atech Manufacturing machinists and turnkey teams work collaboratively and cost-effectively with customers to design, develop, and implement small-to-large turnkey assemblies, from quick-turn prototypes to production quantities and custom projects. This process accelerates the ability to understand the needs, challenges, and desired outcomes of the project.

Our expert machinists and assemblers are skilled at bringing together complex design elements with measureable precision accuracy. More than simply following design specifications, our in-house team can provide special services, including soldering, cabling, and handling optical lenses, solar cells, PCB boards, and lasers components. Our teams are also available for special assembly training as required by a customer or as the project demands.

Total Quality Management

To ensure ultimate precision and workmanship, we use a total quality management strategy to subject every part we produce in-house and every OEM and off-the-shelf (OTS) electrical and/or mechanical component we purchase, to a battery of calibrated quality-control measures. Exacting specifications and tight tolerance limits are guaranteed in every phase of the project.

Atech Manufacturing, 1530 Oakland Road, Suite 120, San Jose, California-95112.